Services

Our Services

Seawater cooling

Installation of SEAWATER COOLING SYSTEMS using cooling-only chillers or heat pumps with EXCHANGERS with TITANIUM plates and buffer tanks. Distribution system using direct production, recirculation or storage tanks.

Read More..

Sea water heating

Installation of seawater HEATING SYSTEMS using boilers with diesel oil, natural gas or propane burners. Heating using auxiliary systems such as cooling circuit water and cogeneration intercoolers, steam circuits, thermal oil, etc. Primary water circuit di

Read More..

Pumping systems and sea water distribution

Seawater PUMPING AND DISTRIBUTION SYSTEMS from intake pit to main regulator tank, pumping from regulator tank to filters and distribution throughout the facility. Installation of Galway cascade pumps and supply PRESSURE CONTROL, supplied to lines with dif

Read More..

Broodstock fish

Installation of BROODSTOCK TANKS, hydraulic systems for distribution of cold and raw seawater. Installation of digital and variable area FLOWMETERS to control the amount of water added to tanks.

Read More..

Hatcheries

Installation of LARVAL TANKS, hydraulic systems for distribution of cold seawater and raw seawater. Installation of digital and variable area FLOWMETERS to control the amount of water added to tanks.

Read More..

Rotifer and artemia

Installation of ROTIFER and ARTEMIA TANKS using individual TITANIUM ELECTRIC RESISTORS or coils with boiler water.

Read More..

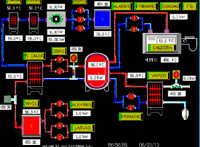

Process Control and Automation

These CONTROL SYSTEMS are not just industrial automation systems, are SPECIALLY DEVELOPED FOR and adapted to the processes in AQUACULTURE FACILITIES, taking the characteristics and details of each process and species farmed into account.

Read More..

Seawater filtration and disinfection

Seawater filtration systems using SAND FILTERS for high flows, ROTATORY FILTERS rotary filters, and cartridge filters with replaceable cartridges for medium flows.

Read More..

Dry pipe, dehumidification and desinfection

Systems for INTERIOR DRYING OF WATER AND AIR DISTRIBUTION PIPES, for both main and reserve lines. Interior drying and DESINFECTION OF SEAWATER PIPES eliminates water remaining after cleaning work on them, eliminating the appearance of bacteria and fungus

Read More..

Air blowers

Installation of blowers for a supply to auxiliary services and tanks. CONSTANT PRESSURE SUPPLY with compressor adjustment matching them to the precise demand at all times. Refrigeration of air dryer and blower rooms to provide dry blown air.

Read More..

Incubation

Installation and conditioning of INCUBATION ROOMS, incubator lighting, water temperature control and room cooling to keep a CONSTANT TEMPERATURE constant temperature during the incubation process. DRYING and FILTRATION of process inflow.

Read More..

Hydraulic installations

Installation of PIPES IN BOILERS AND CHILLER ROOMS, closed primary circuits and open secondary circuits.

Read More..

Renewable Energy

We carry out ENERGY EFFICIENCY STUDIES to check for excess energy consumption, identify places with a performance deficit and find real, effective solutions which help reduce the company's energy costs.

Read More..Energy savings

At AQUAFARM CONCEPTS we are especially COMMITTED TO THE ENVIRONMENT. In all our products and installations, we seek ENERGY SAVINGS AND EFFICIENCY as an essential part of our systems. This means better use of energy resources and economic benefits for our

Read More..